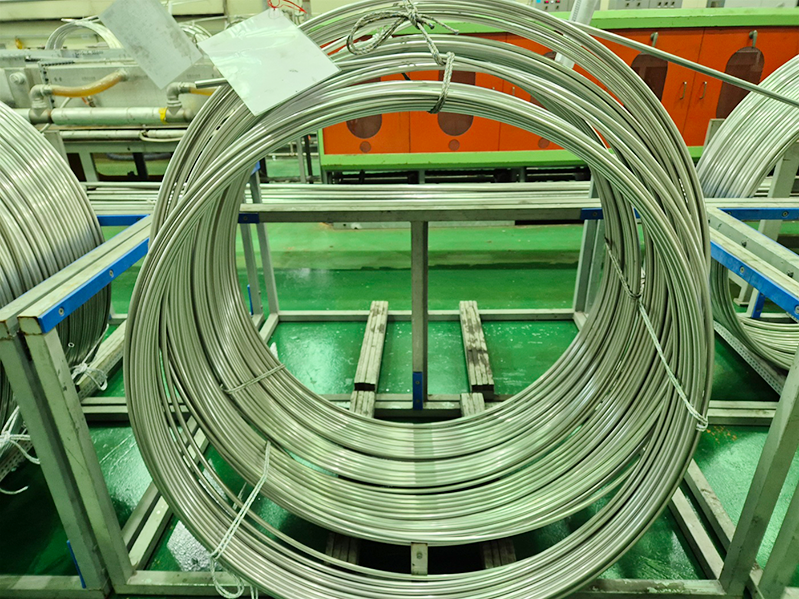

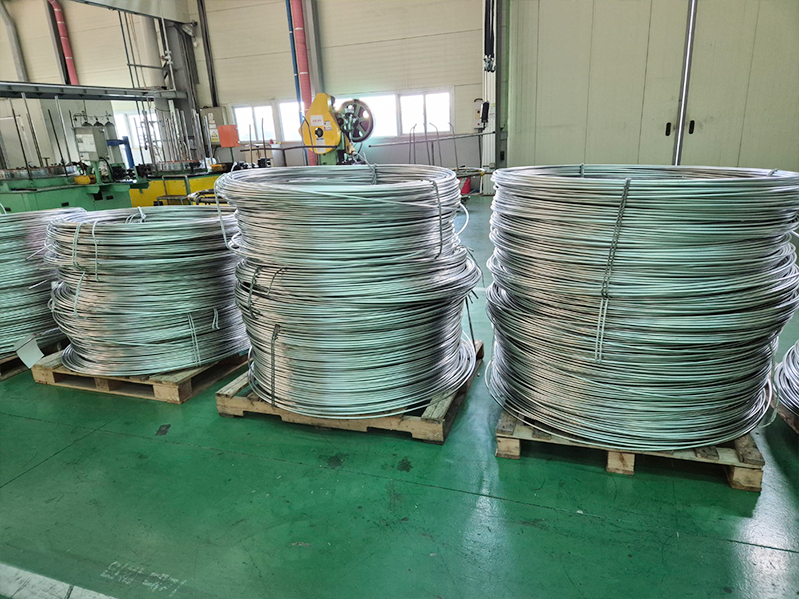

Coil Tube

Coil Tube

Size & Length Detail

| Product | Available Grade | Available Size | Remark | ||

|---|---|---|---|---|---|

| OD | WT | L | |||

| Coil Tube | Refer to the table as follows | 6 to 38.1mm | 0.8 to 4.78mm | Coil | Please consult with us for other size not listed |

Steel Grade Table

| Material | National Standard | |||

|---|---|---|---|---|

| Alloy | ASTM | KS | JIS | |

| Duplex | Duplex | S31803 | STS329 J2 LTB | SUS329 J2 LTB |

| Super Duplex | S32750 | - | - | |

| Super Austenitic | 6 Mo | S31254 | - | - |

| High Alloy stainless Steel | 904L | N08904 | STS 890L | STS 890L |

| Stainless Steel | 316L | TP316L | STS 316L | SUS 316L |

| 316 | TP316 | STS 316 | SUS 316 | |

| 316/L 2.5Mo | TP316L | STS316L | SUS316L | |

| 304 | TP304 | STS 304 | SUS 304 | |

| 317L | TP317L | STS 317L | SUS 317L | |

| 321 | TP321 | STS 321 | SUS 321 | |

| 347 | TP347 | STS 347 | SUS 347 | |

| Nickel Alloy | Monel 400 | N04400 | NW4400 | NW4400 |

| Inconel 600 | N06600 | NCF 600 TB | NCF 600 TB | |

| Inconel 625 | N06625 | NCF 625 TB | NCF 625 TB | |

| Incoloy 825 | N08825 | NCF 825 TB | NCF 825 TB | |

| Hastelloy C22 | N06022 | NW6022 | NW6022 | |

| Hastelloy C276 | N10276 | NW0276 | NW0276 | |

| Copper | Copper | C12200 | C12200 | C12200 |

Size & Length (100kg Weighed Basis)

| Metric Size | Imperial Size | Length(M) (+-10%) |

||

|---|---|---|---|---|

| O.D(mm) | W.T(mm) | O.D(mm) | W.T(mm) | |

| 38.1 | 4.78 | 1-1/2" | 0.188 | 25 |

| 3.05 | 0.120 | 37 | ||

| 2.77 | 0.109 | 41 | ||

| 2.41 | 0.095 | 56 | ||

| 2.11 | 0.083 | 64 | ||

| 31.8 | 3.96 | 1-1/4" | 0.155 | 36 |

| 3.05 | 0.120 | 45 | ||

| 2.77 | 0.109 | 50 | ||

| 2.41 | 0.095 | 56 | ||

| 2.11 | 0.083 | 64 | ||

| 25.4 | 3.05 | 1" | 0.120 | 59 |

| 2.77 | 0.109 | 64 | ||

| 2.41 | 0.095 | 72 | ||

| 2.11 | 0.083 | 81 | ||

| 1.65 | 0.065 | 102 | ||

| 1.24 | 0.024 | 134 | ||

| 19.05 | 2.77 | 3/4" | 0.109 | 89 |

| 2.41 | 0.095 | 100 | ||

| 2.11 | 0.083 | 112 | ||

| 1.65 | 0.065 | 140 | ||

| 1.24 | 0.024 | 180 | ||

| 0.89 | 0.035 | 245 | ||

| 15.88 | 2.11 | 5/8" | 0.083 | 138 |

| 1.65 | 0.065 | 170 | ||

| 1.24 | 0.049 | 220 | ||

| 0.89 | 0.035 | 300 | ||

| 12.7 | 2.11 | 1/2" | 0.083 | 180 |

| 1.65 | 0.065 | 220 | ||

| 1.24 | 0.049 | 283 | ||

| 0.89 | 0.035 | 380 | ||

| 9.53 | 2.11 | 3/8" | 0.083 | 255 |

| 1.65 | 0.065 | 305 | ||

| 1.24 | 0.049 | 390 | ||

| 0.89 | 0.035 | 520 | ||

| 6.35 | 2.11 | 1/4" | 0.083 | 450 |

| 1.65 | 0.065 | 510 | ||

| 1.24 | 0.049 | 630 | ||

| 0.89 | 0.035 | 825 | ||

Size & Range

| mm | WT | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | 1.2 | 1.3 | 1.4 | 1.5 | 1.6 | 1.7 | 1.8 | 1.9 | 2.0 | 2.1 | 2.2 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3.0 | 3.5 | 4.0 | 4.5 | 5.0 | ||

| OD | 38 | ||||||||||||||||||||||||||||||||||

| 32 | |||||||||||||||||||||||||||||||||||

| 31 | |||||||||||||||||||||||||||||||||||

| 30 | |||||||||||||||||||||||||||||||||||

| 29 | |||||||||||||||||||||||||||||||||||

| 28 | |||||||||||||||||||||||||||||||||||

| 27 | |||||||||||||||||||||||||||||||||||

| 26 | |||||||||||||||||||||||||||||||||||

| 25 | |||||||||||||||||||||||||||||||||||

| 24 | |||||||||||||||||||||||||||||||||||

| 23 | |||||||||||||||||||||||||||||||||||

| 22 | |||||||||||||||||||||||||||||||||||

| 21 | |||||||||||||||||||||||||||||||||||

| 20 | |||||||||||||||||||||||||||||||||||

| 19 | |||||||||||||||||||||||||||||||||||

| 13 | |||||||||||||||||||||||||||||||||||

| 18 | |||||||||||||||||||||||||||||||||||

| 17 | |||||||||||||||||||||||||||||||||||

| 15 | |||||||||||||||||||||||||||||||||||

| 16 | |||||||||||||||||||||||||||||||||||

| 14 | |||||||||||||||||||||||||||||||||||

| 13 | |||||||||||||||||||||||||||||||||||

| 12 | |||||||||||||||||||||||||||||||||||

| 11 | |||||||||||||||||||||||||||||||||||

| 10 | |||||||||||||||||||||||||||||||||||

| 9 | |||||||||||||||||||||||||||||||||||

| 8 | |||||||||||||||||||||||||||||||||||

| 7 | |||||||||||||||||||||||||||||||||||

| 6 | |||||||||||||||||||||||||||||||||||

| 5 | |||||||||||||||||||||||||||||||||||

| 4 | |||||||||||||||||||||||||||||||||||

| 3 | |||||||||||||||||||||||||||||||||||

■ Coil Tube ■ Coil & Stick Tube ■ Stick Tube

Working Pressure Table

| Outside Diameter | Wall Thickness | Weight |

Working pressure(bar) Temperature( ℃ ) |

||||||

|---|---|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | kg/m | 20℃ | 100℃ | 200℃ | 300℃ | 400℃ |

| 1-1/2 | 38.10 | 0.098 | 2.50 | 2.231 | 146 | 146 | 141 | 141 | 124 |

| 1 | 25.40 | 0.085 | 2.11 | 1.232 | 205 | 161 | 135 | 121 | 111 |

| 1 | 25.40 | 0.065 | 1.65 | 0.982 | 153 | 120 | 101 | 90 | 83 |

| 3/4 | 19.05 | 0.065 | 1.65 | 0.720 | 209 | 164 | 137 | 123 | 113 | 3/4 | 19.05 | 0.049 | 1.25 | 0.553 | 146 | 115 | 96 | 86 | 79 |

| 5/8 | 15.88 | 0.049 | 1.25 | 0.454 | 178 | 139 | 117 | 105 | 96 |

| 1/2 | 12.70 | 0.065 | 1.65 | 0.456 | 327 | 256 | 215 | 192 | 177 |

| 1/2 | 12.70 | 0.049 | 1.25 | 0.356 | 226 | 177 | 149 | 133 | 122 |

| 1/2 | 12.70 | 0.035 | 0.90 | 0.263 | 146 | 114 | 96 | 86 | 79 |

| 3/8 | 9.53 | 0.049 | 1.25 | 0.257 | 310 | 243 | 204 | 183 | 166 |

| 3/8 | 9.53 | 0.035 | 0.90 | 0.193 | 198 | 155 | 130 | 117 | 107 |

| 1/4 | 6.35 | 0.049 | 1.25 | 0.159 | 496 | 389 | 326 | 292 | 269 |

| 1/4 | 6.35 | 0.035 | 0.90 | 0.122 | 309 | 242 | 203 | 182 | 167 |

Specific Applications

- Hydraulic Power

- Single Transmission

- Monitoring and Control Equipment

- Injection Line

- Down-Hole Safety Valve Control

Our coiled seamless tubing is available in a number of high performance corrosion resistant stainless steel and high nickel alloys, including the 300 series Monel, Inconel, and Hastelloy, capable of withstanding a variety of severe environmental conditions.We specialize in manufacturing small diameter tubing ranging and variety of wall thicknesses. We can supply coiled seamless tubing in loose bulk wound coils, or level wound on various size reels.

Product Application

- Oil, Gas, Petrochemical, Desalination, Fertilizer & Chemical Industries

- Control & Instrumentation Industry (C&I)

- Process & Power Plants

- Valve Remote Control (VRC) Line System

- Deck Machinery Remote Control Line System

- Fixed Gas Detection Sensing Line

- Heat Tracing Line

- Pressure Sensing Line

- Sampling & Drain Line

- Tank Level & Draft Gauging System Line

- Fire Fighting System Control Line

Applied Photo

-

Steel Grade

-

Standard Spec

-

Size & Length Detail

Chemical composition & Mechanical Property of Stainless Steel

| Code | Standard | Chemical Composition | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel Grade |

C (max) |

Si (max) |

Mn (max) |

P (max) |

S (max) |

Ni (max) |

Cr (max) |

Mo (max) |

||

| 304 | ASTM | TP 304 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 11.00 |

18.00- 20.00 |

|

| JIS | SUS 304 | 0.080 | 1.00 | 2.00 | 0.040 | 0.030 | 8.00- 11.00 |

18.00- 20.00 |

||

| DIN | 1.4301 | 0.070 | 1.00 | 2.00 | 0.045 | 0.030 | 8.50- 10.05 |

18.00- 20.00 |

||

| AISI | 304 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 10.50 |

17.00- 20.00 |

||

| 304L | ASTM | TP 304L | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 12.00 |

18.00- 20.00 |

|

| JIS | SUS 304L | 0.030 | 1.00 | 2.00 | 0.040 | 0.030 | 9.00- 13.00 |

18.00- 20.00 |

||

| DIN | 1.4306 | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 12.50 |

18.00- 20.00 |

||

| AISI | 304L | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 12.50 |

18.00- 20.00 |

||

| 316 | ASTM | TP 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 11.00- 14.00 |

16.00- 18.00 |

2.00-3.00 |

| JIS | SUS 316 | 0.08 | 1.00 | 2.00 | 0.040 | 0.030 | 10.00- 14.00 |

16.00- 18.00 |

2.00-3.00 | |

| DIN | 1.4401 | 0.070 | 1.00 | 2.00 | 0.045 | 0.030 | 10.50- 13.50 |

16.50- 18.50 |

2.00-2.50 | |

| AISI | 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 14.00 |

16.00- 18.00 |

2.00-3.00 | |

| 316L | ASTM | TP 316L | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 15.00 |

16.00- 18.00 |

2.00-3.00 |

| JIS | SUS 316L | 0.030 | 1.00 | 2.00 | 0.040 | 0.030 | 12.00- 16.00 |

16.00- 18.00 |

2.00-3.00 | |

| DIN | 1.4404 | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 11.00-14.00 | 16.50-18.50 | 2.00-2.50 | |

| AISI | 316L | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | |

Mechanical Properties

| Grade | UNS | Yield Strength (N/mm²) |

Tensile Strength (N/mm²) |

Elongation (%) |

Rockwell Hardness (Scale) |

|---|---|---|---|---|---|

| TP 304 | S30400 | min 205 | min 515 | min 35 | Max. 90 |

| TP 304L | S30403 | min 170 | min 485 | min 35 | Max. 90 |

| TP 316 | S31600 | min 205 | min 485 | min 35 | Max. 90 |

| TP 316L | S31603 | min 175 | min 485 | min 35 | Max. 90 |

Product Specification

-

Specification

- ASTM A213, A269, A312, JIS G3459, A789, B423, B163, B165

-

MATERIAL

- Austenite stainless steel, Copper / Copper alloy

-

SHEATH MATERIAL

- Flame-retardant PVC / TPU / PE

-

Coil length (Standard length)

- About 550m per wooden reel

- Longer length is available on special request

Standard

| Grade | ASTM (UNS) | Standard | O.D Inch (mm) |

W.T(%) |

|---|---|---|---|---|

| 304 / 304L | S30400 / S30403 | ASTM A269, ASTM A213 | ±0.005 [0.13] | ±10% |

| 316 / 316L | S31600 / S31603 | ASTM A269, ASTM A213 | ±0.005 [0.13] | ±10% |

Seamless Coil Tube

Weight and length Per Coil

| Imperial Size | Metric Size | ||||||

|---|---|---|---|---|---|---|---|

| O.D(in) | W.T(in) | L(ft) | Weight(lb) | O.D(mm) | W.T(mm) | L(m) | Weight(kg) |

| 1/4 | 0.035 | 2,693 | 220~260 | 6.35 | 0.90 | 821 | 100~120 |

| 0.049 | 2,065 | 1.25 | 630 | ||||

| 3/8 | 0.035 | 1,702 | 9.53 | 0.90 | 519 | ||

| 0.049 | 1,273 | 1.25 | 388 | ||||

| 1/2 | 0.035 | 1,245 | 12.70 | 0.90 | 379 | ||

| 0.049 | 921 | 1.25 | 281 | ||||

| 3/4 | 0.049 | 593 | 19.05 | 1.25 | 181 | ||

| 0.065 | 456 | 1.65 | 139 | ||||

| 1 | 0.049 | 437 | 25.40 | 1.25 | 133 | ||

| 0.065 | 334 | 1.65 | 102 | ||||