Jacket Tube

Jacket Tube

XLPE-Sheathed Tube

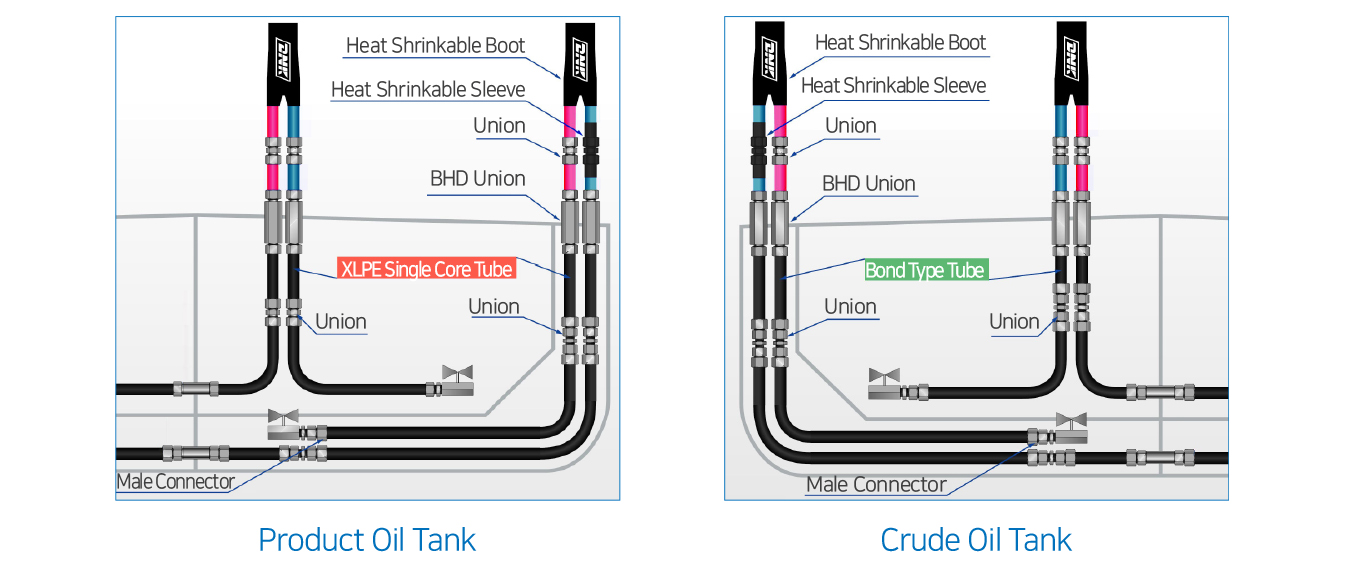

Cross Sectional layer as 1 Core Tube with outer sheath by XLPE material.XLPE sheath is recommended for product oil (Cargo oil, Diesel oil, Gasoline, Jet Fuel oil, Naphtha, etc.) carriers where PVC sheath is not applicable. Shipyards conventionally installed bare tube without sheath in product oil tanks so the tube was bare exposed to corrosion.In order to prevent the possible tube corrosion in the tanks XLPE sheathed single core tube (non-adhesive) is highly recommended for product oil carriers. XLPE material properties are not available with adhesive.

Bond Type Tube

The bond type tube is installed in water ballast tank (WBT) and crude oil tank (COT). This tube has a special adhesive layer. between tube and protective outer sheath, capable of localizing any physical damage of the tube. When compared to conventional use of bare tube (typically 2mm wall) the bond type tube of 0.8-1.0mm wall is commonly adopted, which enables yard’s installation easier and minimizes corrosion of tube in service.

Typical Installation

Sheath Material

| Material | PVC | TCR PVC |

FR PVC |

HFFR TPU |

HFFR PE |

XLPE | TPV |

|---|---|---|---|---|---|---|---|

| Tensile Strength(kgf/mm²) | 1.2~1.4 | 2.0~2.4 | 1.3~1.6 | 2.3~2.8 | 1.0~1.3 | 2.0~2.3 | - |

| Service Temperature (°C) | -40/+70 | -50/+100 | -40/+70 | -50/+90 | -45/+70 | -50/+90 | - |

| Elongation (%) | 250~290 | 340~380 | 250~290 | 400~600 | 500~700 | 420~380 | - |

| Hardness (Shore A or D) |

84~90 (A) | 81~85 (A) | 86~90 (A) | 87~380 (A) | 93~95 (A) | 90~95 (D) | - |

| Halogenated | ○ | ○ | ○ | × | × | × | - |

| Flame Retardant (IEC60332-1) | ○ | ○ | ○ | ○ | ○ | ○ | - |

| Flame Retardant (IEC60332-3-22 Category A) |

× | ○ | ○ | ○ | ○ | ○ | - |

Please consult us for other materials not listed.

TCR : Thermal & Cold Resistance, FR : Flame Retardant,

HFFR : Halogen Free & Flame Retardant,

XLPE : Cross-Linked Polyethylene, TPU : Thermo Plastic

Polyurethane