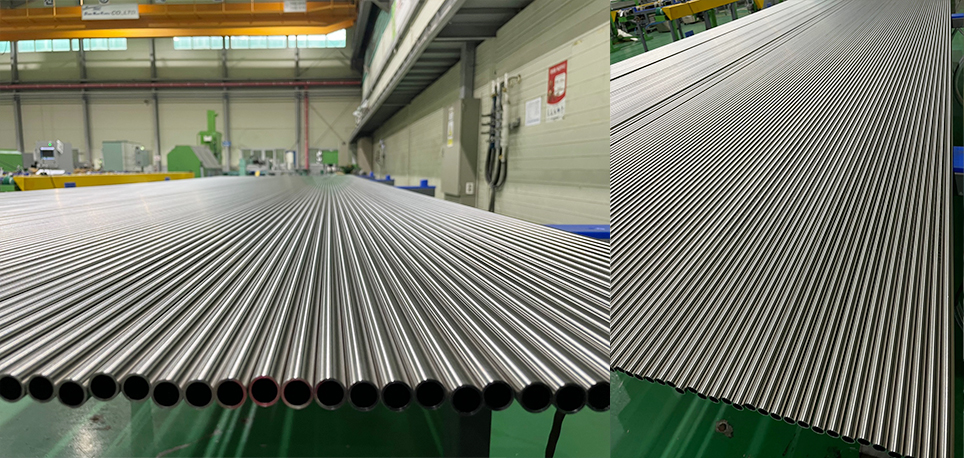

Straight Tube

Welded Straight Tube

Product Features

Welded tubes to precise specifications through the Welding - Cold drawing -BA heat treatment process. These procedures dramatically overcome weakness of weld beads and makes it possible to produce precision tubes for a variety of demanding applications.

Corrosion Resistant

Material Selection

| Alloy | PREN | Density | Application Alloy | |

|---|---|---|---|---|

| g/㎤ | lb/㎤ | |||

| 304 | 21 | 7.93 | 0.29 | General good corrosion resistance grade |

| 304L | 21 | 7.93 | 0.29 | Lower carbon than 304 impedes carbide precipitates in heat affected zone giving good weld ability. Reduced carbides also lowers susceptibility to intergranular corrosion |

| 316 | 24 | 7.98 | 0.29 | Alloyed with molybdenum which improves corrosion resistance in marine environments, chlorides, and biofouling. Excellent pitting corrosion resistance. |

| 316L | 24 | 7.98 | 0.29 | Carbon content restricted, which impedes carbide precipitates in heat affected zone giving good weld ability. Reduced carbides also lowers susceptibility to intergranular corrosion |

-

Steel Grade

-

Standard Spec

-

Size & Length Detail

Chemical composition & Mechanical Property of Stainless Steel

| Code | Standard | Chemical | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steel Grade |

C (max) |

Si (max) |

Mn (max) |

P (max) |

S (max) |

Ni (max) |

Cr (max) |

Mo (max) |

||

| 304 | ASTM | TP 304 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 11.00 |

18.00- 20.00 |

|

| JIS | SUS 304 | 0.080 | 1.00 | 2.00 | 0.040 | 0.030 | 8.00- 11.00 |

18.00- 20.00 |

||

| DIN | 1.4301 | 0.070 | 1.00 | 2.00 | 0.045 | 0.030 | 8.50- 10.05 |

18.00- 20.00 |

||

| AISI | 304 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 10.50 |

17.00- 20.00 |

||

| 304L | ASTM | TP 304L | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 8.00- 12.00 |

18.00- 20.00 |

|

| JIS | SUS 304L | 0.030 | 1.00 | 2.00 | 0.040 | 0.030 | 9.00- 13.00 |

18.00- 20.00 |

||

| DIN | 1.4306 | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 12.50 |

18.00- 20.00 |

||

| AISI | 304L | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 12.50 |

18.00- 20.00 |

||

| 316 | ASTM | TP 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 11.00- 14.00 |

16.00- 18.00 |

2.00- 3.00 |

| JIS | SUS 316 | 0.08 | 1.00 | 2.00 | 0.040 | 0.030 | 10.00- 14.00 |

16.00- 18.00 |

2.00- 3.00 |

|

| DIN | 1.4401 | 0.070 | 1.00 | 2.00 | 0.045 | 0.030 | 10.50- 13.50 |

16.50- 18.50 |

2.00- 2.50 |

|

| AISI | 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 14.00 |

16.00- 18.00 |

2.00- 3.00 |

|

| 316L | ASTM | TP 316L | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 15.00 |

16.00- 18.00 |

2.00- 3.00 |

| JIS | SUS 316L | 0.030 | 1.00 | 2.00 | 0.040 | 0.030 | 12.00- 16.00 |

16.00- 18.00 |

2.00- 3.00 |

|

| DIN | 1.4404 | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 11.00- 14.00 |

16.50- 18.50 |

2.00- 2.50 |

|

| AISI | 316L | 0.030 | 1.00 | 2.00 | 0.045 | 0.030 | 10.00- 14.00 |

16.00- 18.00 |

2.00- 3.00 |

|

Mechanical Properties

| Grade | UNS | Yield Strength (N/mm²) |

Tensile Strength (N/mm²) |

Elongation (%) |

Rockwell Hardness (Scale) |

|---|---|---|---|---|---|

| TP 304 | S30400 | min 205 | min 515 | min 35 | Max. 90 |

| TP 304L | S30403 | min 175 | min 485 | min 35 | Max. 90 |

| TP 316 | S31600 | min 205 | min 485 | min 35 | Max. 90 |

| TP 316L | S31603 | min 175 | min 485 | min 35 | Max. 90 |

Product Application

- Oil, Gas, Petrochemical, Desalination, Fertilizer

& Chemical Industries

- Control & Instrumentation Industry (C&I)

- Process & Power Plants

- Valve Remote Control (VRC) Line System

- Deck Machinery Remote Control Line System

- Fixed Gas Detection Sensing Line

- Heat Tracing Line

- Pressure Sensing Line

- Sampling & Drain Line

- Tank Level & Draft Gauging System Line

- Fire Fighting System Control Line

Product Specification

-

Tube Specification

- ASTM A213, A269, A312, JIS G3459

A789, B423, B163, B165 etc. -

TUBE MATERIAL

- Austenitic stainless steel

-

SHEATH MATERIAL

- Flame-retardant PVC / TPU / PE

-

Pipe & Tube length (Standard length)

- Basic Length unit 4~6meter

- Other pipe & tubes are also available upon request

-

Coil length (Standard length)

- About 550m per wooden reel

- Longer length is available on special request

Standard

| Grade | ASTM (UNS) | Standard | O.D In.(mm) |

W.T(%) |

|---|---|---|---|---|

| 304 / 304L | S30400 / S30403 | ASTM A269, ASTM A213 | ±0.005 [0.13] | ±10% |

| 316 / 316L | S31600 / S31603 | ASTM A269, ASTM A213 | ±0.005 [0.13] | ±10% |

Welded Coil Tube

Weight and length Per Coil

| Imperial Size | Metric Size | ||||||

|---|---|---|---|---|---|---|---|

| O.D(in) | W.T(in) | L(ft) | Weight(lb) | O.D(mm) | W.T(mm) | L(m) | Weight(kg) |

| 1/4 | 0.035 | 2,693 | 220~260 | 6.35 | 0.90 | 821 | 100~120 |

| 0.049 | 2,065 | 1.25 | 630 | ||||

| 3/8 | 0.035 | 1,702 | 9.53 | 0.90 | 519 | ||

| 0.049 | 1,273 | 1.25 | 388 | ||||

| 1/2 | 0.035 | 1,245 | 12.70 | 0.90 | 379 | ||

| 0.049 | 921 | 1.25 | 281 | ||||

| 3/4 | 0.049 | 593 | 19.05 | 1.25 | 181 | ||

| 0.065 | 456 | 1.65 | 139 | ||||

| 1 | 0.049 | 437 | 25.40 | 1.25 | 133 | ||

| 0.065 | 334 | 1.65 | 102 | ||||

Welded Straight Tube

Technical Data

| PRODUCT | GRADE | AVAILABLE SIZE | REMARK | ||

|---|---|---|---|---|---|

| DIAMETER | THICKNESS | LENGTH | |||

| STRAIGHT TUBES | AUSTENITE ( 304, 304L, 316, 316L ) |

6 to 25.4mm (1/4” ~1” ) |

0.8 to 2.11mm | 4m,6m |

Coiled tubes Upon request |